The process flow of extrusion molding includes stages such as raw material pretreatment, plastic melting and mixing, extrusion molding, cooling and shaping. Firstly, the raw materials are dried, mixed, and melted, and then the melted plastic is extruded out of the mold or die head through an extruder. After cooling, the molded plastic product is obtained. The entire process requires precise control of parameters such as temperature, pressure, and speed to ensure product quality and production efficiency.

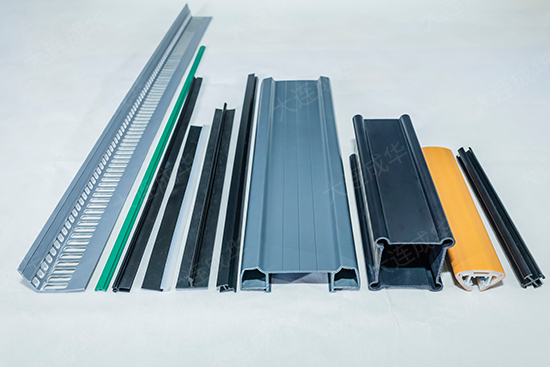

In rubber processing, extrusion molding is used to manufacture products such as sealing strips and rubber tubes. Extrusion molding can achieve high elasticity and wear resistance of rubber products, improving their service life. In metal processing, extrusion molding is mainly used to manufacture products such as aluminum profiles and copper pipes. Through extrusion molding, precision forming and high strength of metal products can be achieved, while also improving the utilization rate of metals and reducing waste.

How to improve the surface smoothness of extruded products in Dalian?

Optimize extrusion process parameters: Firstly, optimize the extrusion molding process parameters, including adjustments to extrusion temperature, pressure, speed, and other parameters. Reasonable process parameters can ensure uniform flow of extruded materials, reduce the generation of bubbles and defects, and thus improve the surface smoothness of the product.

Choosing appropriate raw materials: Choosing high-quality raw materials is crucial for improving the surface smoothness of products. High quality raw materials not only ensure the physical and chemical properties of the product, but also reduce the generation of defects and bubbles, and improve the surface smoothness of the product.

Optimizing mold design: Optimizing mold design can effectively improve the surface smoothness of products. By adjusting the mold structure and surface finish, the flow of the product during extrusion is smoother, reducing the generation of defects and bubbles, thereby improving the surface finish of the product.

Strengthen equipment operation and maintenance: Regularly inspect and maintain extrusion molding equipment to maintain its good condition and ensure stable and smooth operation. Poor operation of the equipment can lead to defects and unevenness on the surface of the product, affecting its smoothness.

Strengthen quality control: Establish a strict quality control system, conduct comprehensive testing and inspection of extruded products, and ensure that the products meet quality standards. Timely detection and handling of surface defects and flaws in products, fundamentally improving the surface smoothness of products.

Extrusion molding is a common plastic processing method, also known as extrusion molding. It is a process that uses an extruder to extrude melted plastic material into a specific shape through heating and pressure. Extrusion molding is usually suitable for producing plastic products of various shapes, such as pipes, sheets, profiles, etc. It is one of the important methods in plastic processing and widely used in the industrial field.

Extrusion molding is a common plastic processing method, which uses an extruder to heat and melt plastic raw materials before extruding them into various shapes of plastic products. Maintaining molding accuracy is crucial during the extrusion molding process, as it directly affects the quality and performance of the final product.